Kanban and Personal Kanban

Kanban is a visual process developed by Taiichi Ohno of Toyota to ensure that everyone on the shopfloor is aware of the requirement for the day and produces only as much product at their workstations as is required by the customer. Any over or under production is immediately visually communicated to all the other workstations so that corrective action can be immediately undertaken. The process helps to ensure:

- Only that much work is undertaken as is possible for the factory to achieve without creating disharmony. This borrows from the Toyota Pull system (discussed later) that advocates that the Factory works only as much as is required by the customer and to never overproduce and create buffer stocks.

- Any deviation from the plan is immediately made known to all people responsible for the process so that corrective action can be immediately taken. This is done by simple visual or auditory alarms or indicators.

Several experts in the field have already applied this technique at the individual level, to help in mapping work to be done, and to take up only those jobs that can be done without a system overload, and has a simple but effective way to track and monitor the To Do list.

Please check out “Personal Kanban – Mapping Life, Navigating Work” by Jim Benson or read his excellent presentation at http://www.slideshare.net/ourfounder/personal-kanban-101

Kaizen or Continuous Improvement

The typical ‘Kaizen’ or Continuous Improvement System in Lean Management consists of the following steps:

a) The workplace is divided into small teams of workers involved with one activity. These cells are called Quality circles

b) The Workers meet each week and list out:

i. a brief review of the previous weeks work

ii. what worked and what didn’t, with respect to the cell’s goals, which in turn are aligned to the organizations goals

iii. suggestions for improvements

iv. a brief note to senior management with a justification for any investment required to effect improvements in the system.

c) Workers have the power to effect these changes within their quality Circle.

d) Senior Management does a review of all the reports from Quality Circles and approves investments/any major changes that affect several departments.

d) This process is repeated every week. The cumulative change by this process is so dramatic over a longer term that many work processes are so improved as to be practically unrecognizable.

The Underlying philosophy in this is that the worker is the best judge on what works best at the shop floor, not a senior executive sitting at some place far away from the scene of action.

The Personal Kaizen System:

A Coaching equivalent of Kaizen, or Personal Kaizen, could work as explained below:

a) The Client makes a list of all the critical actions required to be undertaken. This could be done by several conventional methods, such as the Wheel of Life, or 65 and Back.

b) This then is cascaded into annual, monthly and weekly plans.

c) Every week, the Client does a review of all actions as per b) in the previous section. Of course, the ‘Senior Management’ would be the Client, with possibly a Coach for support.

d) Any decisions that require cooperation/approval of the stakeholders – Family/Friends/Work associates would need to be negotiated at regular intervals.

The process continues week after week with perhaps a quarterly review of what worked and what did not. Any corrective action based on the review could be taken at this point.

Improving processes by Value Stream Analysis

An Important Lean Management tool is Value stream analysis. In this, all important tasks are broken up into value adding and non-value adding tasks. These are then analysed and changes made in the process. The process could be changed by changing equipment, changing layouts, modifying sub-processes, and reducing or completely eliminating tasks that are non-value adding.

In manufacturing organizations, it has been observed that this initiative once again provides dramatic improvements – Major reduction in cycle time (sometimes more than 90%), or process stock levels (greater than 50%) are not unusual.

Can something similar be done in personal improvement?

Here is a case:

Key task – Obtain Coaching certification in 4 months.

This key task could be broken down as:

- Listing all the work to be done in the period – This would include ALL work done during a waking day of approximately 16 hours, such as meals, personal work, entertainment, and other work along with the Certification work.

- The time spent for each task in a day is then determined. An analysis is made of the value addition for each task. This would be an important decision exercise and sufficient support systems would need to be put in place to facilitate the Client to make such a transition.

- For instance, a typical schedule for a particular week could look like:

| Sl No | Task | Initial Hours spent | Value Adding (H/M/L) | Revised plan |

| 1 | Attend Tele-classes | 6 | H | 10 |

| 2 | Post on Forum | 8 | H | 10 |

| 3 | Research for Review Paper | 4 | H | 5 |

| 5 | Non Coaching Consultancy Work | 20 | H | 20 |

| 6 | Scrabble Competition | 10 | L | 0 |

| 7 | Dinner Engagement | 4 | H | 4 |

| 8 | Relaxation – TV | 6 | M | 3 |

| 9 | Relaxation – Reading | 4 | M | 3 |

| 10 | Miscellaneous – Meals, personal work etc | 30 | M | 25 |

| Total | 92 | 80 | ||

| Total Available waking hours (16 x 5) | 80 |

Once this is prepared, sufficient support systems must be offered to the Client to assist in the transition to a modified lifestyle.

It is quite possible that this exercise could be an eye-opener for the Client in helping him realise where time is being spent on ‘non-value’ adding activities. If the Client is able to genuinely discover this for himself, it should energise the Client to address and complete the high priority value adding activities with higher energy levels and with no undue effort.

The Personal Pull System

Oftentimes, we come across people who seem to lead charmed lives. They are able to accomplish all their tasks with consummate ease, and have time to manage their lives and do several things simultaneously. They have equanimity in whatever they do, and do not seem to be tense or rushed. Could it be that they have consciously or unconsciously mapped out their key stakeholders and are in harmony with what each stakeholder expects? And their equanimity (and success) comes from the fact that they are aware of their capabilities and have tailored their deliverables to meet the expectations of their stakeholders in a harmonious way?

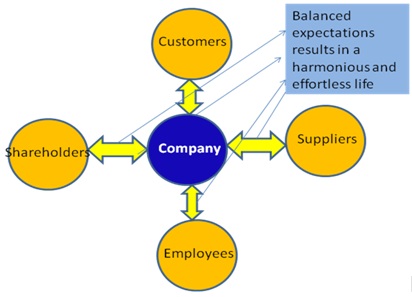

Such a system at a Corporate Level is fundamental to the Toyota system of Management – the requirements of the key stakeholders – Customers, Employees, Suppliers and Shareholders are assessed carefully and listed out.

The workflow is planned in such a manner that there is no undue strain on the Company in addressing the demands of each stakeholder. There is no over or under-estimation of needs and all subsequent actions are harmonised towards a smooth flow (Figure 2).

On the other hand, conventional organizations overestimate customer demand and build large finished goods stocks. Similarly, they underestimate supplier capabilities and build large inventories. This leads to a large amount of time and effort invested wastefully.

The Pull system perfected by Toyota ensures that the entire system hums along, with the pull from the customer defining all back-end action.

Can a similar harmony be created by fashioning a Pull System for the Individual?

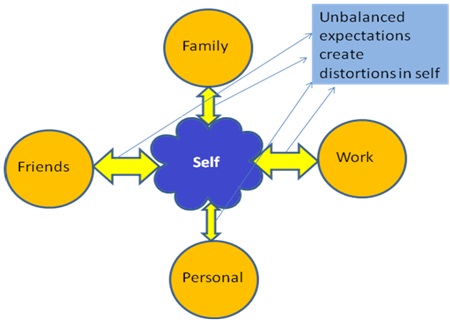

A typical individual is suppressed to various pulls and pressures from stakeholders – Work, Family, Friends and Personal Goals. When there is an imbalance in the estimation of needs of each stakeholder, the ‘Self’ gets distorted as seen in Figure 3.

What could be done to re-establish harmony?

a) A careful reassessment of one’s capabilities is the starting point.

b) A reassessment of the expectations of key stakeholders is the next step.

c) Creating a smooth pull system that ensures that there are no undue pulls and pressures comes next.

d) At this point, it is possible that there could still be an imbalance in expectations from some of the stakeholders.

e) If so, an action plan using some of the tools and techniques listed above could help in working towards the balance.

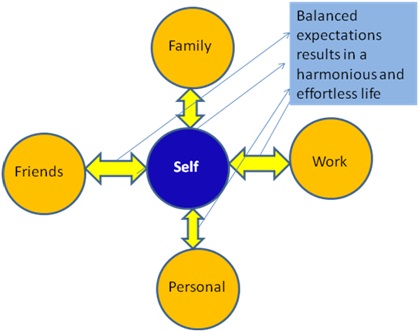

If the exercise is properly executed, the harmonious self as shown in Figure 4 can be regained.

So what could be possible steps in creating the Personal Pull system?

a) Establish where the priorities at that moment in life are: Toyota clearly creates a Pull system around Customer requirements, and all other actions feed into that. In the case of a Personal Pull system, the priorities may vary depending on the individual and also on the individual’s priorities in life at that moment.

b) Create a set of actions that ensure that no stakeholder demand is neglected or over emphasised.

c) Manage and monitor the set of actions, using the techniques described above, or other appropriate processes.

Figure 4 – The Harmonious Self

Figure 4 – The Harmonious Self

d) Create a Personal Kaizen to improve the Flow and provide better service to the stakeholders.

Conclusion:

There is no doubt that several techniques in Lean Management can indeed be applied for personal growth and productivity. Some techniques, like Personal Kanban, have already been honed into organized systems for self improvement.

The other techniques described in the paper could indeed be used and perfected for organized application. As my research did not find any systematic study in this field, except for Personal Kanban, the approaches suggested by me are fundamentally preliminary and would require further research for fine tuning and applicability.

If the approaches could be perfected, it is very possible that these techniques could open a new Client Segment – those who have been previously seen the efficacy of these techniques in manufacturing and would readily identify with them for application: as also other Clients who may not have been exposed to this system, but are drawn towards the holistic, harmonious and systematic philosophy on which the Toyota System of Lean Manufacturing is based.

Bibliography:

Lean Thinking – James P Womack and Daniel T Jones

The Toyota Way – Jeffrey K Liker

‘ Personal Kanban’ – Jim Benson